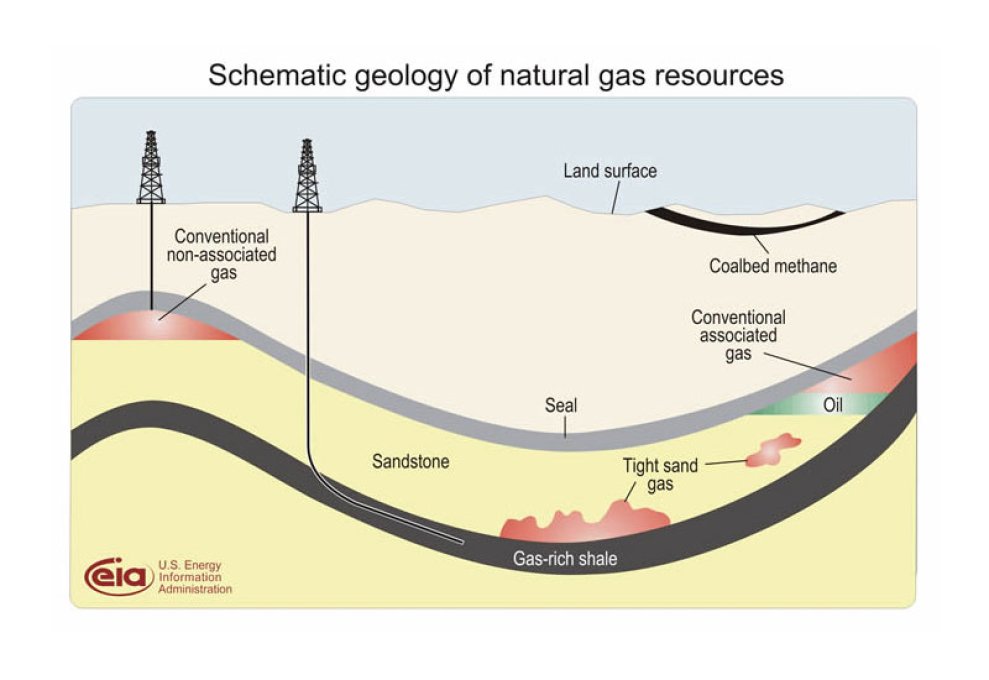

Hydraulic fracturing represents an unconventional form of natural gas exploitation. When the extraction process requires a stimulating treatment (such as a chemical or hydraulic aid), a resource is considered „unconventional“. In order to extract shale gas of sedimentary rock, this technology commonly referred to as „fracking“ is necessary. The word „fracking“ is a diminutive for hydraulic fracturing, it was first performed in 1947 in limestone deposits.

Shale rocks have a very low permeability, which means that its gases are held in the pores of the stone. Hydraulic fracturing consists in the targeted dislocation of such rock layers. Shale reservoirs are so deeply located, that there might not be sufficient porosity and reservoir pressure to allow shale gases to flow from the rock into the well. Therefore, a high-pressured injection of liquid is used to crack the rock. Fracking can be done near the earth’s surface, or very deeply underground (more than 1 km and even 4 km sometimes). A variety of liquids are used in the process: chemicals, water, mud, or technical fluids enriched with agents such as sand for example.

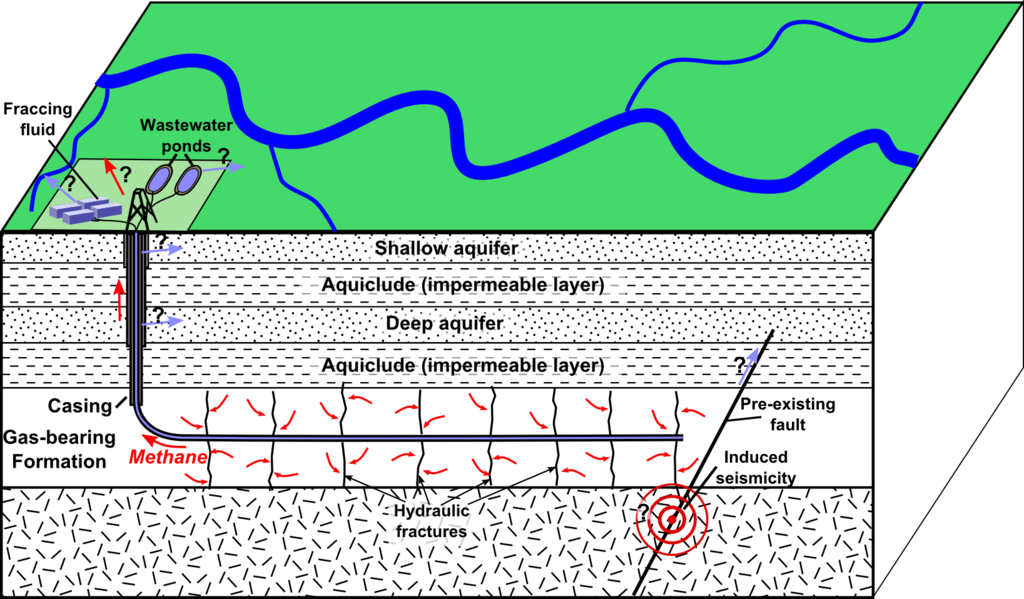

The first step consists in drilling down vertically to the shale gas reservoirs. Once the well has been drilled and the pipe has reached a shale gas deposit, the drill is turned by 90° so that it is channelled horizontally through the rock layer. The vertical part of the pipe is consolidated and fortified in order to avoid any outflows of gas or water in the aquifers and the soil. At horizontal level, holes are punched into the surrounding rock using explosive charges. A mixture of water, sand and chemicals is then pumped into the well at high pressure. The water forces the gas out of the pores of the shale, while the grains of sand fill the pores and prevent them from collapsing. The chemicals in the water act as lubricants. When the pressure decreases, the gas comes up through the well to the surface. There is about 20 to 30% of flowback waters, the rest remains in the well and in the fractures.

The unconventional extraction process involves possible risks such as the contamination of soil and water and the resulting environmental impact.

There is a risk of ground water contamination from leaking methane during the fracturing process. Freshwater aquifers usually lie at 100m below the surface, groundwater contamination can therefore occur around a vertical drill that is not sufficiently fortified and secured. However, methane can also be found close to groundwater sources and contamination might therefore occur without external force. Wether the link between methane emissions and the fracking process is actually causal or only correlated, is thus subject to an ongoing debate. The movie „Gasland“ (2010) by Josh Fox brought methane contamination that occured near fracking exploitation sites in the US to widespread public attention.

Other environmental concerns involve the impact of toxic chemicals that are pumped into the shales along with sand and water during the drillings. These chemicals partially remain in the well and fractures and therefore might be absorbed by the surrounding sedimentary rock.

While the main industrial use of hydraulic fracturing is stimulating production from oil and gas wells, hydraulic fracturing is also applied to stimulating groundwater wells, preconditioning rock for caving or inducing rock to cave in mining, as a means of enhancing waste remediation processes (usually hydrocarbon waste or spills), disposal of waste by injection into deep rock formations, as a method to measure the stress in the earth, or for heat extraction to produce electricity in enhanced geothermal systems.